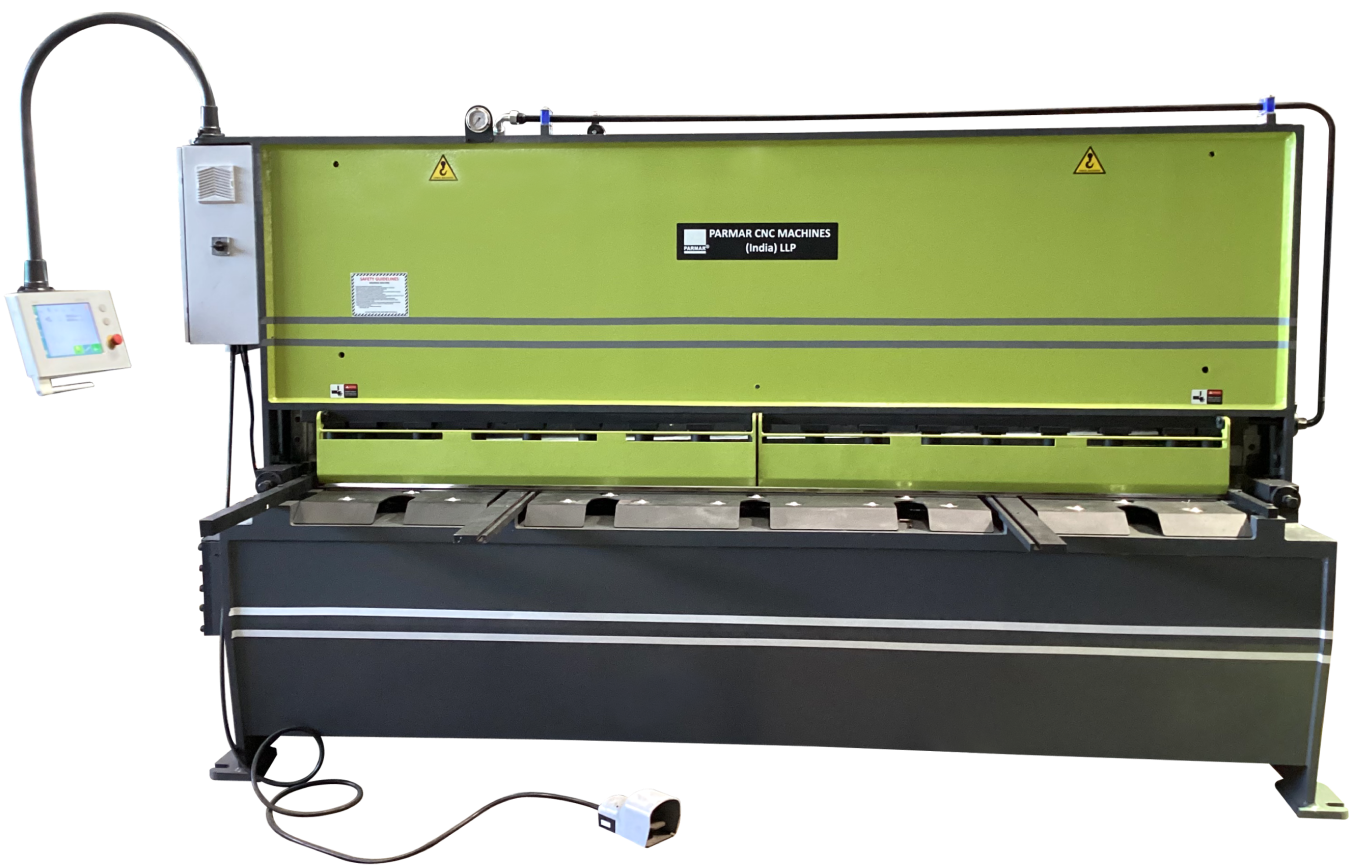

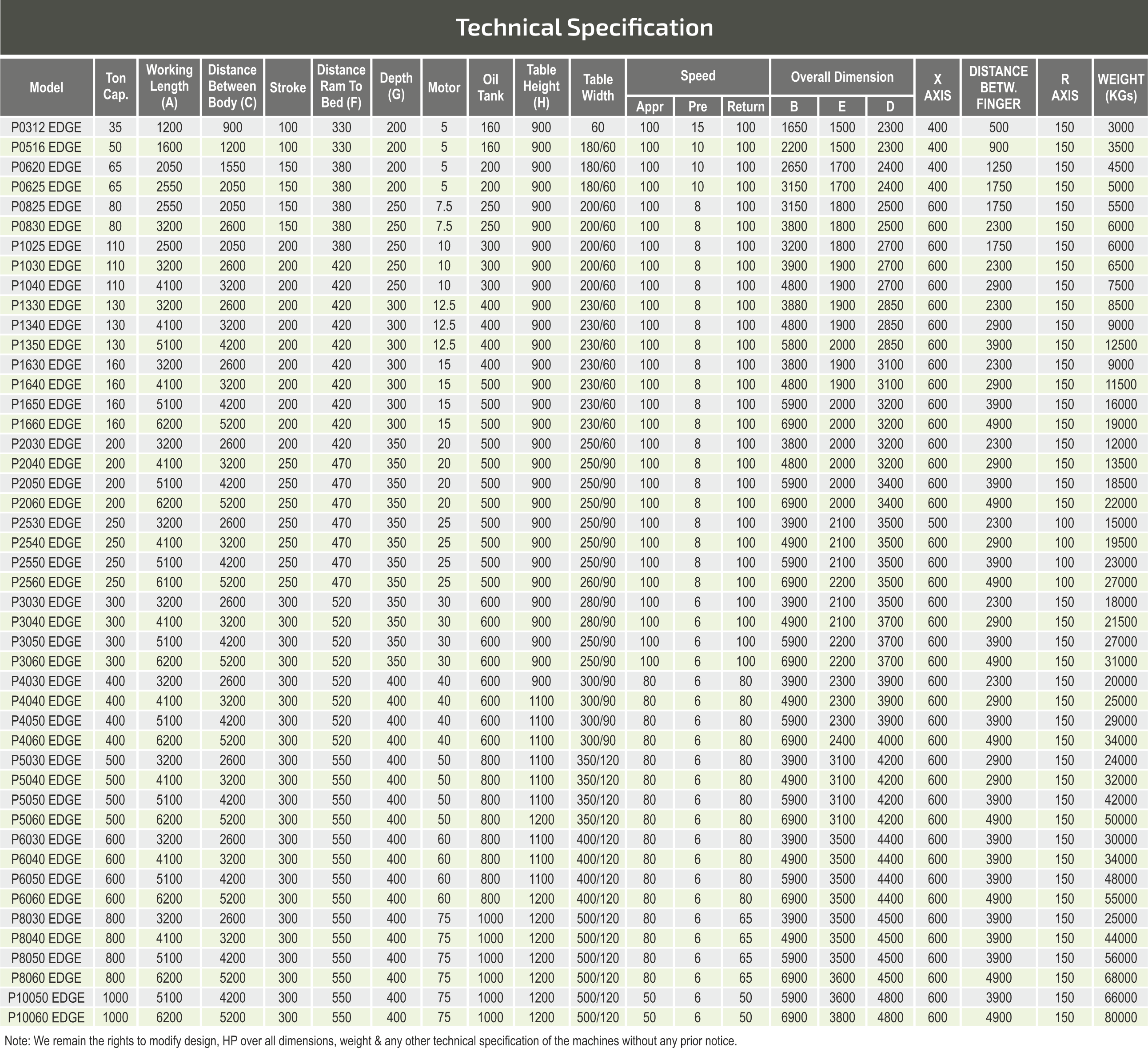

VARIABLE RACK ANGLE HYDRAULIC SHEARING MACHINE

CNC SERIES

PARMAR is manufactured Hydraulic Variable Rake Angle Shears which is rated as one of the best in the markets due to its tensile strength and robust build. The rake angle is adjustable to suit thickness and material; the sheets are clamped hydraulically before cut starts. These are designed and developed to shear plates with clean square edges. Further, these come with close working tolerances with options of different rake angles.

We are a quality centric organization, therefore we fabricate our products implementing sophisticated technologies in accordance with the international quality standards. This shearing machine is highly praised by the clients for its smooth functionality and large scale production capability.

Standard Features:

- Front Sheet Support

- Rear Gauge by Front Operated

- One Suitable Five Way Die

- Punch

- Manual Operated Lubrication System

- Pair of Lifting Links

- Movable Operation Console With

Foot Switch & Various Operation Push Buttons - Main Motor Drive

- Die Clamp

- Electric Control Panel with Selection of

'Auto', 'Inch' & 'Single' Cycle Mode Operation

Optional Accessories:

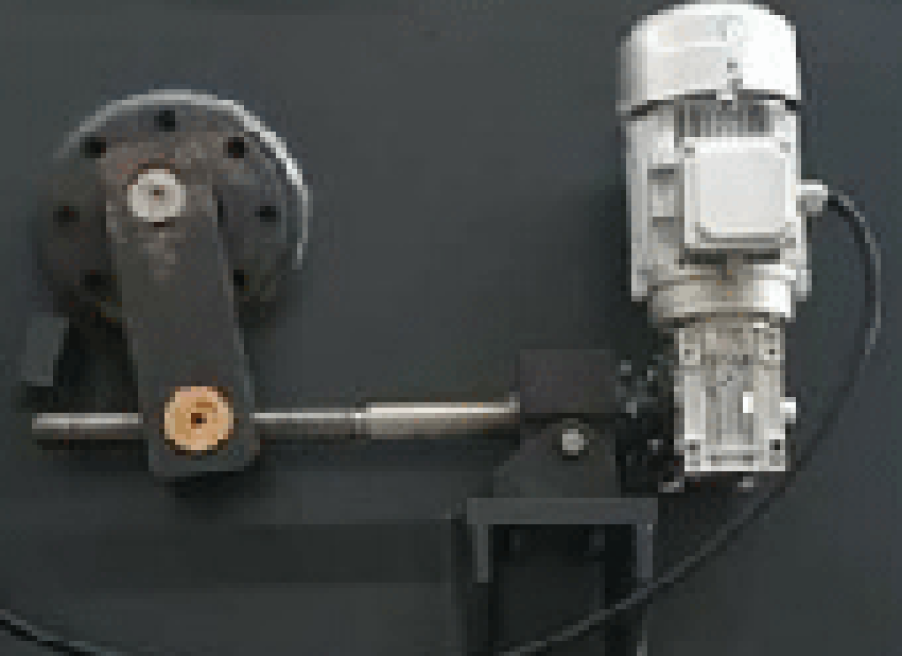

- Motorised Back Gauge with PLC

- Anti Detection System

- Sliding Sheet with Swing Away Supports

- Extra Depth

- NC Controller

- Extra Horns

SHEARING CONTROLLER

OUR EXCELLENCE

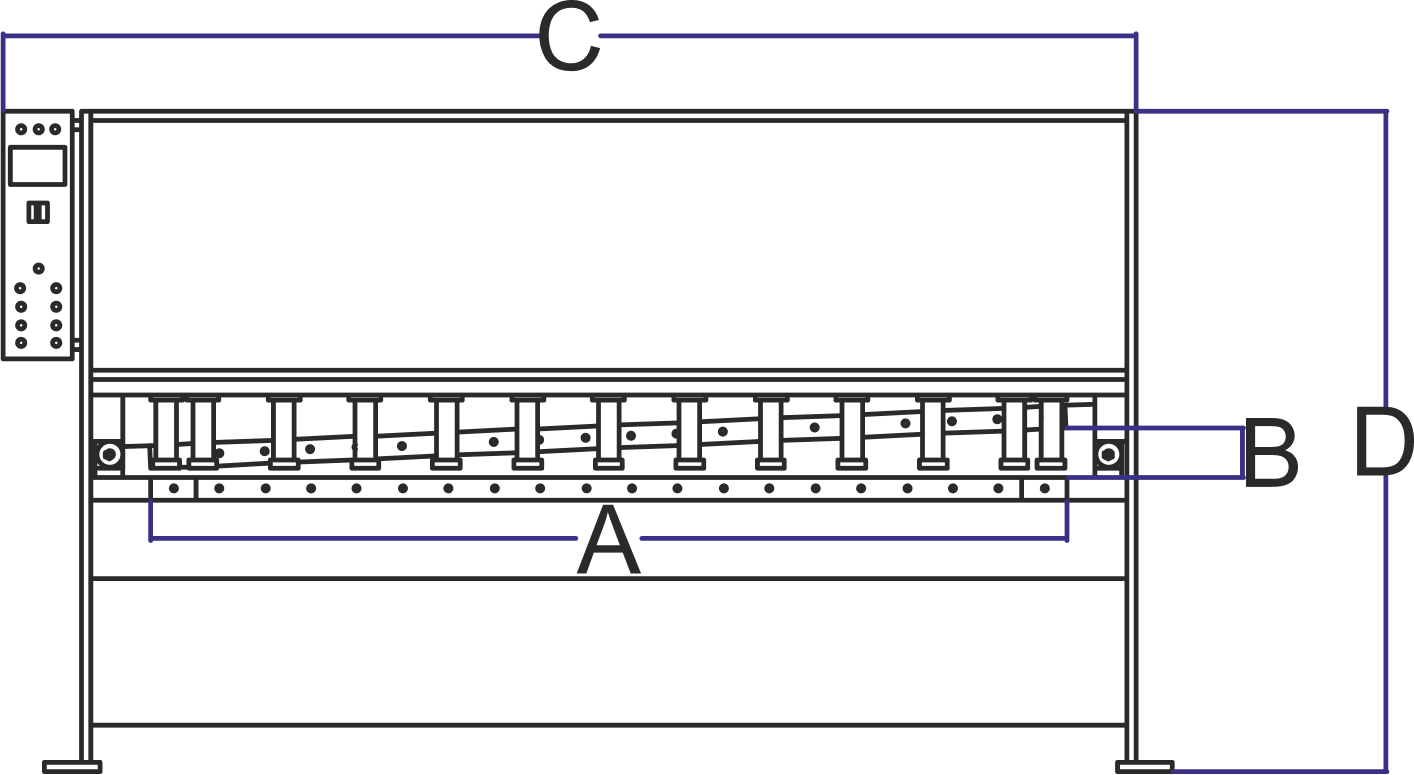

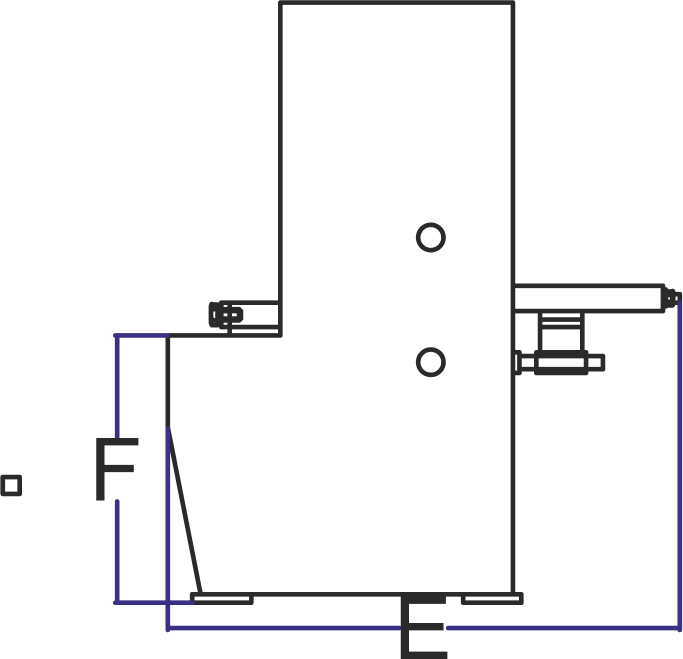

Back Gauge

Automatic Blade gap system

Automatic sheet 2 stop sheet support